electrical discharge machining working principle

Milling covers a wide variety of different operations and machines on scales from small individual parts to large heavy-duty gang milling operations. This method is based on the principle that when a small obstacle is placed in the surface of a stream ripples are formed when.

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Electrical Discharge Machining.

. 8 Differential temperature between top and bottom on barrel within 20C. The working principle is water is coming from the storage reservoir through a penstock to the Inlet of the nozzle which is the inlet of the turbine so the hydraulic energy of the water is mainly converted into kinetic energy. 1 Electrical Discharge Machining EDM GOPINATHG MECHANICAL.

The hot gases produce are discharge through a nozzle in the form of a jet with a very high velocity. Rectangular dog-bone shaped tensile specimens with gauge dimensions of 3 mm 4 mm 25 mm thickness width length were prepared by electrical discharge machining. 2 The disparities between the laws or administrative measures adopted by the Member States regarding the restriction of the use of hazardous substances in electrical and electronic equipment EEE could create barriers to trade and distort competition in the Union and may thereby have a direct impact on the establishment and functioning of the internal market.

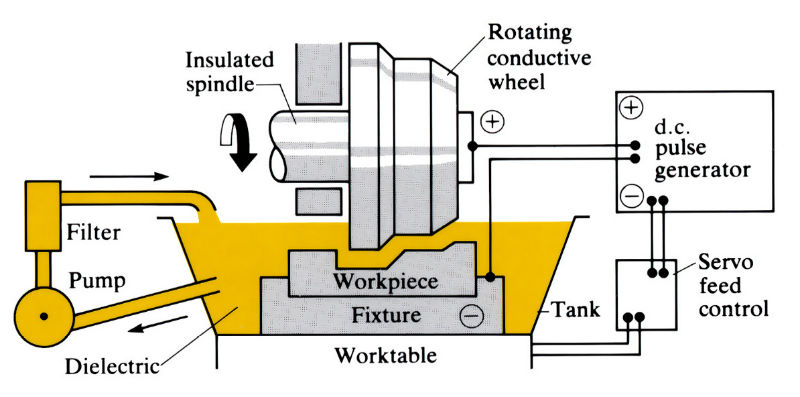

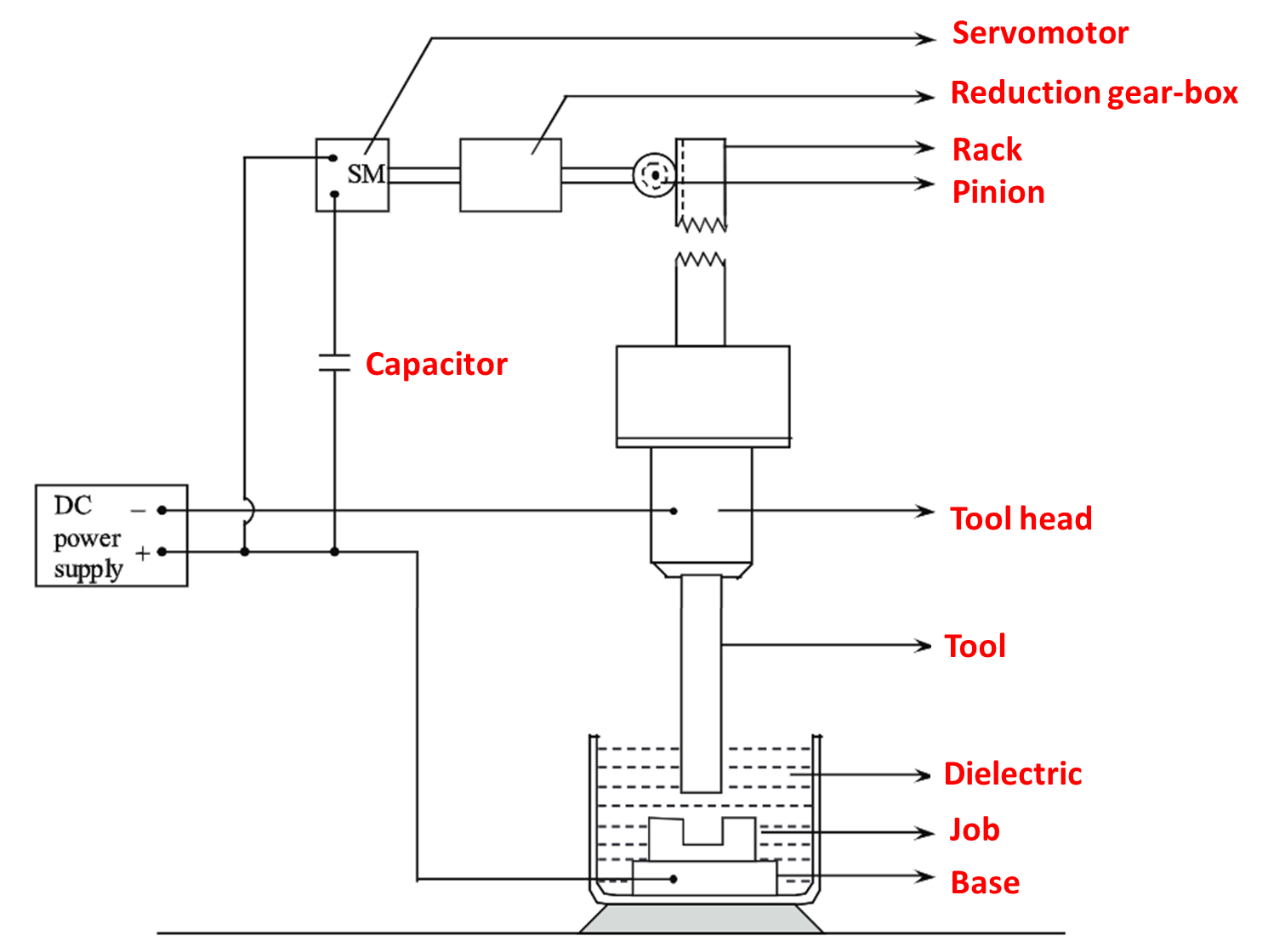

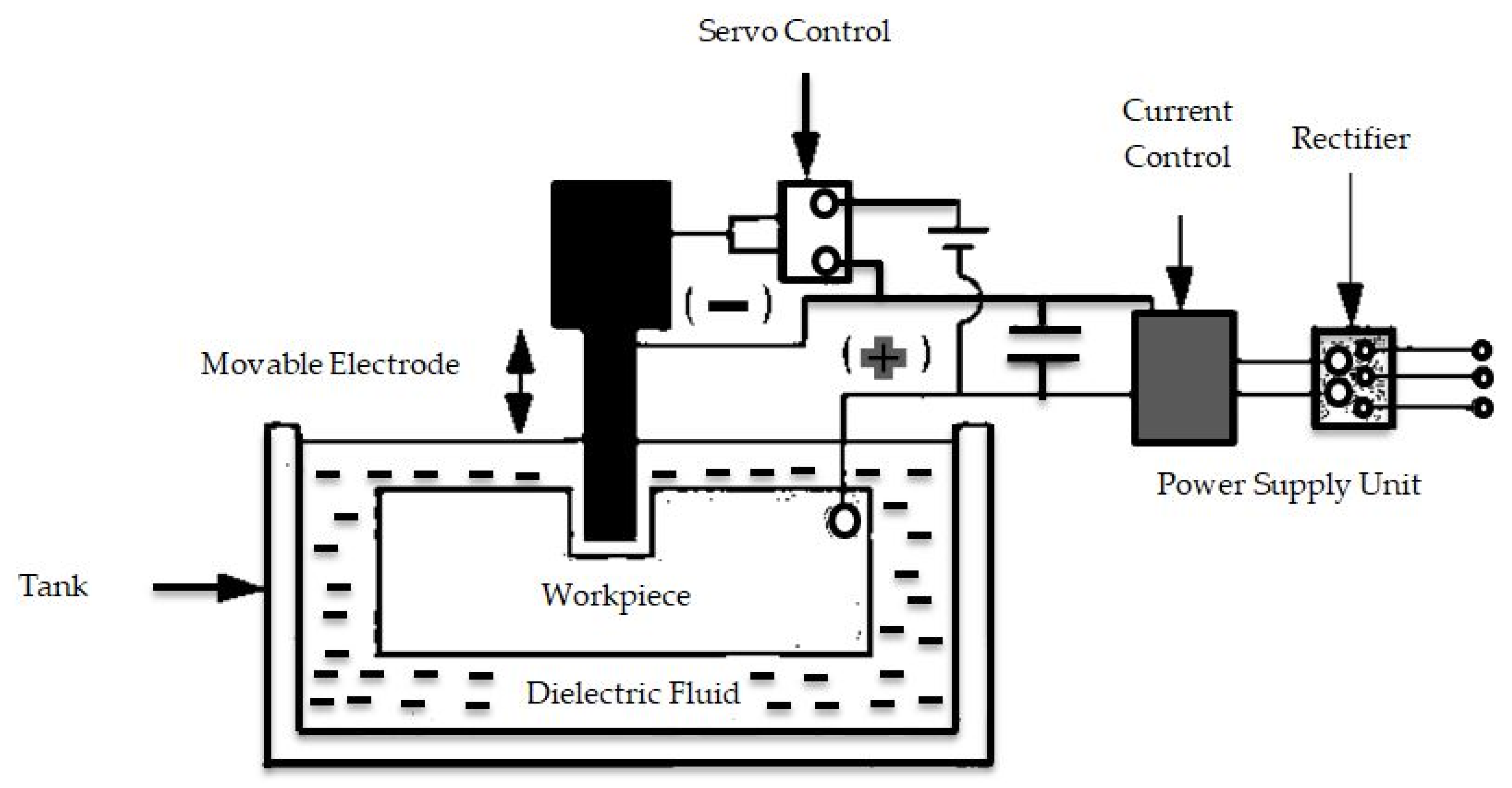

The rate of heat transfer increases as the velocity of flow past the wire increases. This alternating current reaches the transducer where it is converted to high-frequency mechanical vibrations. The workpiece is fixed in the dielectric container using a fixture.

EDM Electrical Discharge Machining Process. A machine tool is a machine for handling or machining metal or other rigid materials usually by cutting boring grinding shearing or other forms of deformationsMachine tools employ some sort of tool that does the cutting or shaping. Working Principle of Electrical Discharge Machining.

Turning to course help online for help is legal. Non-road mobile machinery made available exclusively for professional use means machinery with an on-board power source the operation of which requires either mobility or continuous or semi-continuous movement between a succession of fixed working locations while working and is made available exclusively for professional use. In the process first the pressure of water is increased to a few thousand bars and then the pressure energy is converted into kinetic energy of the water jet.

Investment Casting Process. Getting assignment help is ethical as we do not affect nor harm the level of knowledge you are expected to attain as a student according to your class syllabus. It is also known as spark erosion and spark machining.

The jet propulsive engine may divide into two distinct types That which uses atmospheric air as its oxidant turbo. Electroencephalography EEG is a method to record an electrogram of the electrical activity on the scalp that has been shown to represent the macroscopic activity of the surface layer of the brain underneath. Auto repair 3 auto repair 1 Automobile 90 career 2 electrical engineering 2 Engineering Material 6 fluid mechanics 30 heat transfer 4 industrial engineering 4 KOM 21 learn autocad yourself 15 machining 1 Mechatronics 6.

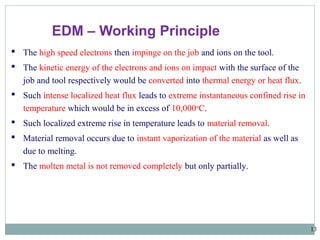

If the bonding energy of the electrons is less electrons would be emitted. Pumps Start and Check. As soon as the power supply is switched on Alternating Current is generated by the transformer because of the mutual inductors present in it.

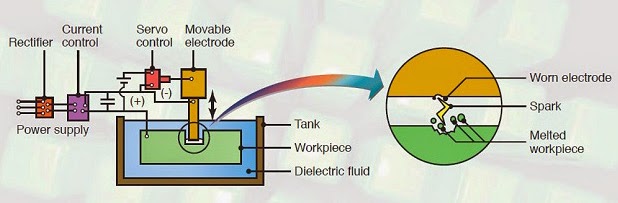

This method is generally used for machining hard materials. Firstly the gap voltage is applied across the tool electrode and workpiece. So lets dive into the article.

Electrochemical machining ECM is a method of removing metal by an electrochemical process. Ultrasonic machining USM Abrasive jet machining AJM 1. It is normally used for mass production and is used for working extremely hard materials or materials that are difficult to machine using conventional methods.

Electrical Discharge Machining EDM is a machining technique through which the surface of a. ECM can cut small or odd-shaped angles intricate contours. Get 247 customer support help when you place a homework help service order with us.

1 Oil supply pressure 2 Pump suction pressure 3 Pump discharge pressure 4 The passing of the minimum flow 5. History of Abrasive Water Jet Machining As you. It consists of an electric power supply the dielectric medium the tool.

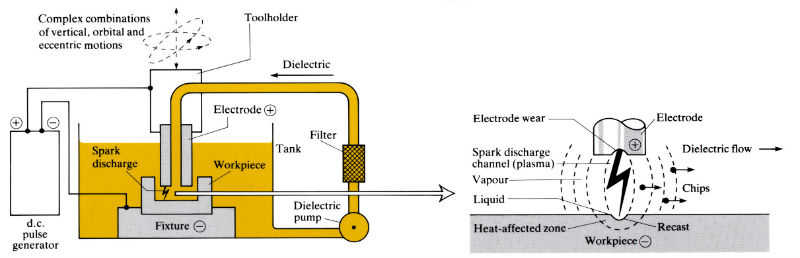

Working Application Advantages and Disadvantages. In the last article we had discussed the basics of the Machining process whereas in Todays article we will discuss the Abrasive Water Jet Machining Process along with its Definition Construction Working Principle Process Parameters Application Advantages Disadvantages. In this process electrical energy is used to generate the Spark between the tool and workpiece submerged under the dielectric medium so that material removal takes place from the surface of the workpiece by local melting or Vaporization.

11 As the electric field is established between the tool and the job the free electrons on the tool are subjected to electrostatic forces. The equiaxed grains were obtained with an average grain size of 5 μm. 4 Discharge valve closed 5 Minimum flow shut-off valve open 6 Cooling water system running 7 Oil pump in operation.

It is typically non-invasive with the electrodes placed along the scalp. Working Principle Of Water Jet Machining. Our services are here to provide you with legitimate academic writing help to assist you in learning to.

Electro-discharge machining or EDM is one of the most commonly used non-traditional methods of machining. EDM Working Principle 11. Working with us is legal.

Electrical discharge machining 1. The electrical resistance of the wire is related to its temperature which depends upon the heat transfer to the surrounding fluid. Now Working Pelton Wheel Turbine Working Principle.

The basic principle is shown in Figure 51. Electrical Discharge machining is the process of metal removal from the work surface due to an erosion of metal caused by electric spark discharge between the two electrodes tool cathode and the work Anode. Electricity is the set of physical phenomena associated with the presence and motion of matter that has a property of electric chargeElectricity is related to magnetism both being part of the phenomenon of electromagnetism as described by Maxwells equationsVarious common phenomena are related to electricity including lightning static electricity electric heating.

All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Working Principle of Electrical Discharge Machining Process. Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpieceThis may be done by varying direction on one or several axes cutter head speed and pressure.

Water jet machining works on the principle of erosion of the area on which the high-velocity water jet strikes. Electrocorticography involving invasive electrodes is sometimes called intracranial EEG. Figure 2 illustrates the working mechanism of the EDM process.

This produces a required thrust in opposite direction known as a propulsive force which is responsible for moving the vehicle. It is also known as Spark Machining or Spark Eroding process. Thus the electric field is created in the gap between them.

Its use is limited to electrically conductive materials. In the previous article we had discussed Electron Beam Machining Ultrasonic Machining Electrical Discharge Machining and Electrochemical machining whereas in todays article we will learn various concepts of Water Jet Machining along with its Definition Construction Working Principle Types Applications Advantages Disadvantages in a detailed way. Electrical discharge machining is a process in which electrical energy is used to generate the Spark between the tool and workpiece.

We will guide you on how to place your essay help proofreading and editing your draft fixing the grammar spelling or formatting of your paper easily and cheaply. Working Principle Of an Ultrasonic Welding Equipment.

Electrical Discharge Machining How Edm Machine Works

Electro Discharge Machining Process Working Animation Video Explained With Setup Diagram Youtube

Electric Discharge Machining Advantages Disadvantages

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Electrical Discharge Machining

Principle Of Electric Discharge Machining Download Scientific Diagram

Electrical Discharge Machining Principle Working Equipment S Advantages And Disadvantages With Diagram Mech4study

Electrical Discharge Machining An Overview Sciencedirect Topics

Mechanical Students Community On Twitter Electric Discharge Machining Edm Principle Working Advantages Limitations Applications Https T Co Khzmxbtufc Https T Co Pwj9tnaia1 Twitter

2 Schematic Of An Electric Discharge Machining Edm Machine Tool Download Scientific Diagram

Edm Process Note Edm Electrical Discharge Machining Download Scientific Diagram

Mechanical Engineering Electrical Discharge Machining Edm Principles

What Is Electrical Discharge Machining Edm Process Diagram Advantages Applications Electricalworkbook

What Is Electrical Discharge Machining Edm Process Quora

What Is Electrical Discharge Machining Edm Process And How It Works Mechanical Booster

Micromachines Free Full Text Recent Advances And Perceptive Insights Into Powder Mixed Dielectric Fluid Of Edm Html

Electrical Discharge Machining Principles And Applications Rapiddirect

Electrical Discharge Machining An Overview Sciencedirect Topics